Copyright © 2021 Hanly SMT All rights reserved.

Reflow Oven

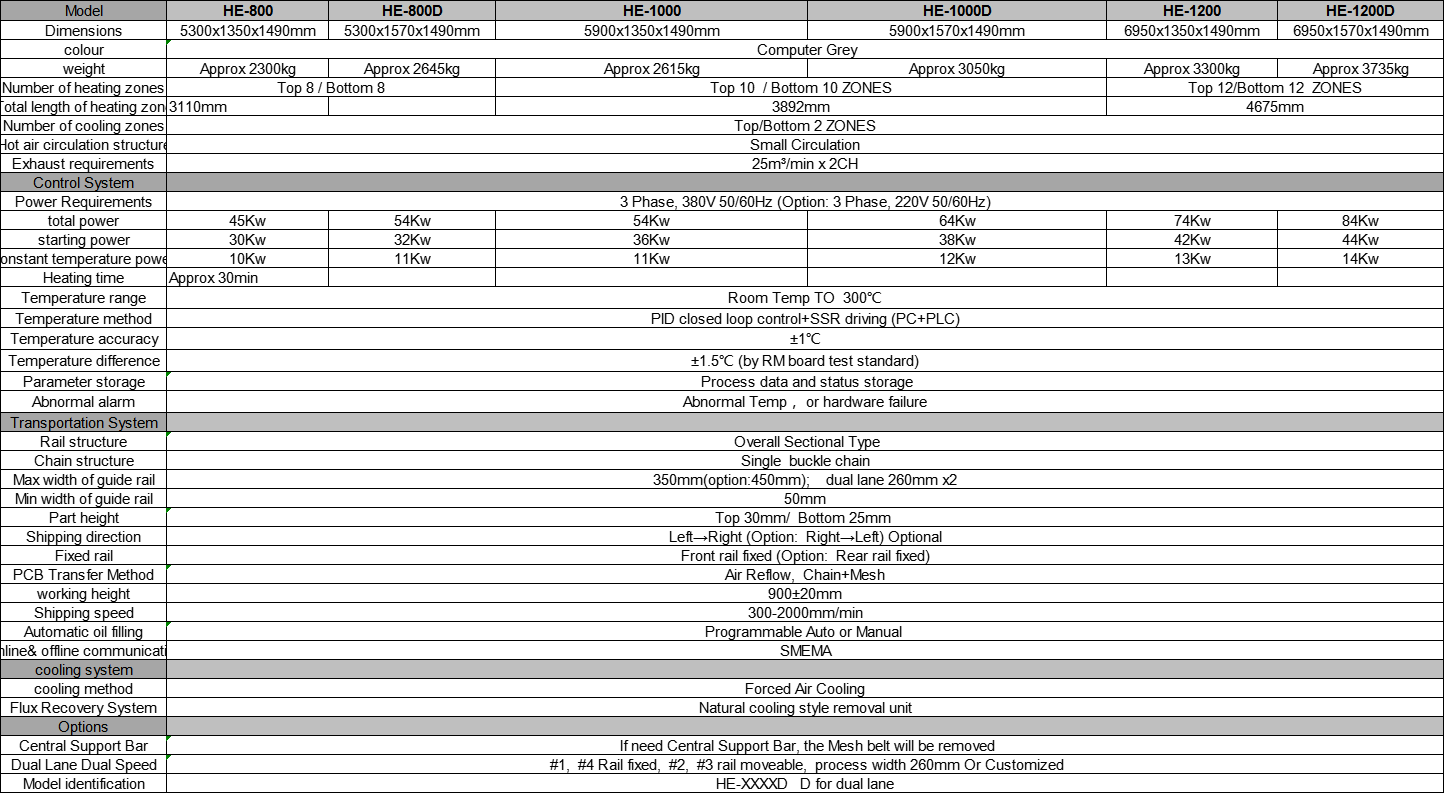

HE Series Reflow Oven

Technical Details

Features:

Hot air supply system

1 The upper and lower independent heating modules, small circulating air, the air temperature is uniform and heat compensation is faster.

2. Each temperature zone is controlled by PLC for PID closed-loop control, and the temperature control is accurate;

3 The unique zoned flexible heating control system reduces the starting power and network voltage drop, and minimizes your power consumption and high performance;

4 Efficiently accelerate the air duct, greatly improve the circulating hot air flow, and heat up rapidly

5 The modular design of the heating area and the drawer design of the heating wire make maintenance and maintenance extremely easy;

6 The uniform air plate is 3mm aluminum plate; further make the heat energy transfer more stable

7. The electric screw lifting mechanism, the span space of science and technology, makes the lifting of the upper furnace body safe and reliable without deformation;

8 Flux recovery system, making it more reliable to remove flux residues;

9. Optimized hot air, recirculation system enhances the efficiency of heat transfer;

Transportation System

1 The chain is automatically lubricated and tensioned to ensure smooth transportation of the PCB;

2. The mesh belt transmission and chain transmission are parallel at the same speed, and are controlled by the computer in a fully closed cycle, which can meet the simultaneous production of different varieties of PCB;

3 High-strength guide rail design, small thermal deformation, ensure accuracy;

4. The width of the guide rail adopts a speed-regulating motor, which is manually controlled, which is convenient and easy to use;

5. The computer automatically controls the lubricating guide rail;

6 Transportation method: mesh belt and chain;

7 The new single I-shaped guide rail lifting and pushing system is more convenient to adjust and ensures that the guide rail is not deformed;

8 Double rail structure (option)

cooling system

1 2-zone forced air cooling system for fast cooling of the PCB (eutectic formation in a shorter time),

2 Ultra-long cooling area, which is conducive to full cooling of PCB after soldering;

Control System

1 WIN-7 operating system, convenient man-machine dialogue;

2 Equipped with an item number protector to ensure the safety of operators and control systems;

3 It can store all the temperature and speed settings of the user and the temperature curves under the settings, and can analyze all the data and curves;

4 Built-in UPS and automatic delay shutdown system to ensure that PCB and reflow machine will not be damaged when power failure or overheating;

5 The control system adopts Siemens PLC+ computer, the stable operation of PLC does not need to rely on the computer for a long time, so as to avoid the production stop due to the computer crash.