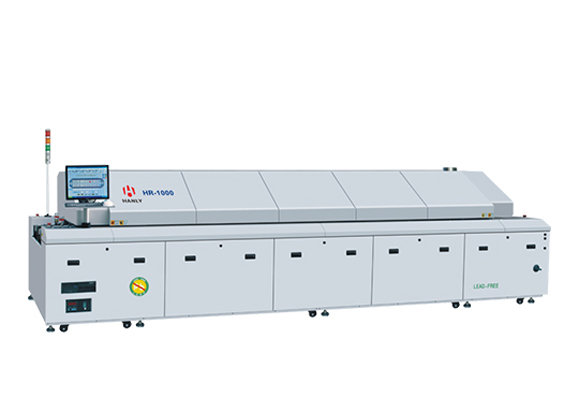

HE Series

HE Series Lead Free Reflow Soldering Machine

¤ Suitable For Computer, Communication & Consumable Products/High Throughput Requirement

¤ 8, 10, 12 Heating Zones Available

¤ Single/Dual Lane Configuration Available

¤ Option Of Center Rail Support

¤ SIEMENS PLC+Computer Controlled, High Reliability

¤ High Performance Heat Preservation, Power Saving

¤ Temperature Accuracy In +/- 1°C

¤ Advance Small Circulation Structure, High Thermal Conduction With Low Across Temperature Deviation

¤ Fast Thermal Compensation With High CPK Index

¤ Heating Zone Air Flow Adjustable

¤ 2 Zones Forced Natural Air Cooling/Option Of External Water Chiller

¤ Flux Management Unit Meet With Environmental Protection Requirement

¤ SMEMA Interface

¤ User Friendly Control Interface, Real Time Monitoring Of Machine