Copyright © 2021 Hanly SMT All rights reserved.

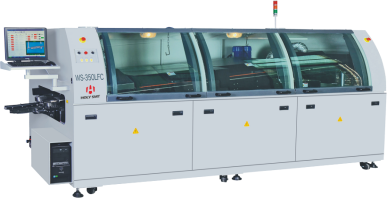

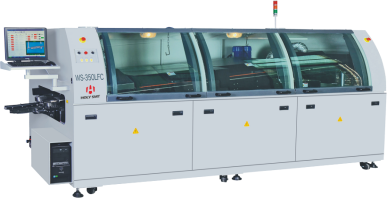

Wave Soldering

WS-350

Technical Details

| Model | WS-350 |

| Size | L4250×W1360×H1650mm |

| Weight | 1200kg |

| Color | Computer grey |

| Basic parameters | Be |

| Equipment control | Win 7 + PLC Control Windows |

| Control interface | Chinese/English |

| Number of preheat zones | 3 ZONES |

| Total length of preheating zone | 1600mm |

| Infrared compensation | 90mm |

| Number of cooling zones | 1 |

| cooling slope | Natural Air Cooled: 3-4°C/sec |

| Exhaust requirements | ≥3m³/sec×2 |

| Compressed air requirements | >4kg/cm² |

| Power Requirements | 3 Phase 5 Cables 380Vac 50/60Hz |

| starting power | ≦29.5kw |

| operating power | ≦9.5kw |

| Heating time | Pre-Heat: Approx 15min Solder Pot: Approx 90min |

| Temperature setting range | Preheating : Room Temp-200℃ Soldier Pot: Room Temp-300℃ |

| temperature control method | PID Closed Loop Controlled |

| Temperature control accuracy | ±1℃ |

| Transverse temperature difference | ±2℃ |

| Hot air flow | Approx 50CFM |

| heat release from the environment | ≦9OJ Joule |

| ambient noise | ≦60db decibel |

| Production Data | Product production files; fault statistics Board Recipes, SPC Data, Alarm & Fault History |

| working width | 50-350mm |

| working height | 750mm±30mm |

| transport rate | 0-1800mm/min |

| Adjustable angle of guide rail | 4. -7. |

| Product allowable height | Reference To Finger Grooves; TopsSide≥100mm; Underneath≥15mm |

| Flux part | |

| Nozzle driving method | Step motor driving |

| spray height | 50-80mm |

| degree of atomization | 20-40 microns differential |

| Nozzle diameter | 1.3mm |

| Flux capacity | 20 liters |

| Flux replenishment | Automatic (Option: External pressure tank) |

| External sprayer | Optional |

| Transmission part | |

| Transmission direction | Left→Right L→R or Right→Left R→L(Selectable) |

| Rail fixing method | Front Fixed (optional) |

| Transmission power | 220Vac 90W |

| transfer method | Finger Type,Doudle V-Groove Titanium Fingers |

| central support | Wire Type Center Board Support |

| Rail width adjustment | Manual Width Adjustment |

| Chain claw cleaning | 220Vac 30W |

| preheating part | |

| Preheat power | 220Vac 16kw |

| heating method | Hot Air Convection-50CFM |

| Hot air motor power | 220Vac 125W 2800rpm |

| Tin cylinder part | |

| Tin cylinder power | 220Vac 12kw |

| Tin cylinder capacity | 380kg |

| Tin cylinder material | Stainless steel 316L (Option: Titanium TA1 Titanium TA1/ Cast Iron with ceramic coating) |

| crest height | 0-12mm |

| crest spacing | 1st and 2nd wave spacing Between Chip & Lambda 36mm |

| Tin cylinder in and out | Electric Motorized |

| Tin dross production | 0.19-0.21kg/hr |

| cooling section | |

| cooling method | Natural Air Cooled |

| Other function configuration | |

| failsafe | Overload, Overtemp & Missing Phase Protection, Board Jam Alert |

| error alarm | Buzzer Alarm,Monitor Display & Light Tower |

| nitrogen structure | Option: N2 Consumption(<500ppm) :≦20m3/hr |

| Nitrogen accessories | Option: Oxygen Analyser & Nitrogen Flow Meters |

| temperature curve system | 3ch Profiling System With Analytical Software |

| Backup power supply | 1000W, 15-20min |