Copyright © 2021 Hanly SMT All rights reserved.

Wave Soldering

WS-200

Technical Details

Features:

1 Substrate automatic input device

2. Rosin spray system (using special Japanese nozzle, Japanese SMC cylinder swings back and forth to spray flux, PLC control;

3 Transmission track (stepless speed regulation of Japanese Panasonic motor, double fishing type titanium claws to ensure more stable clamping of the circuit board;

4 Preheater (using imported thyristor relay PID temperature control, ceramic infrared preheating control)

Double wave tin furnace

The furnace is made of 316 stainless steel, which can effectively prevent the corrosion of the furnace after long-term use, and the phenomenon of tin leakage will not occur in the inner tank;

(a) The tin spray port of the furnace is specially designed, and the width of the PCB can be adjusted freely, which is an ideal design for lead-free welding at present;

(b) The adjustment in the groove can make the single-sided wave smoothly realize. The spray wave crest can effectively realize the dispensing welding of SMD components;

(c) Using imported electronic frequency conversion to adjust the amount of tin spraying, and accurately adjust the height of the crest;

(d) The special anti-oxidation furnace structure is adopted to effectively prevent the formation and accumulation of semi-oxides, and the daily amount of tin oxidation can be greatly reduced;

(e) The furnace chamber of the tin furnace adopts an external heating plate structure, which can reduce the amount of tin loaded in the furnace chamber, and can reduce the number of solder joints in the furnace chamber to prevent tin leakage;

(f) Cooling fan

(g) Claw washer (imported water pump)

(h) Control box (full set of imported control components)

(i) One-week time setting, one-week work schedule can be prefabricated

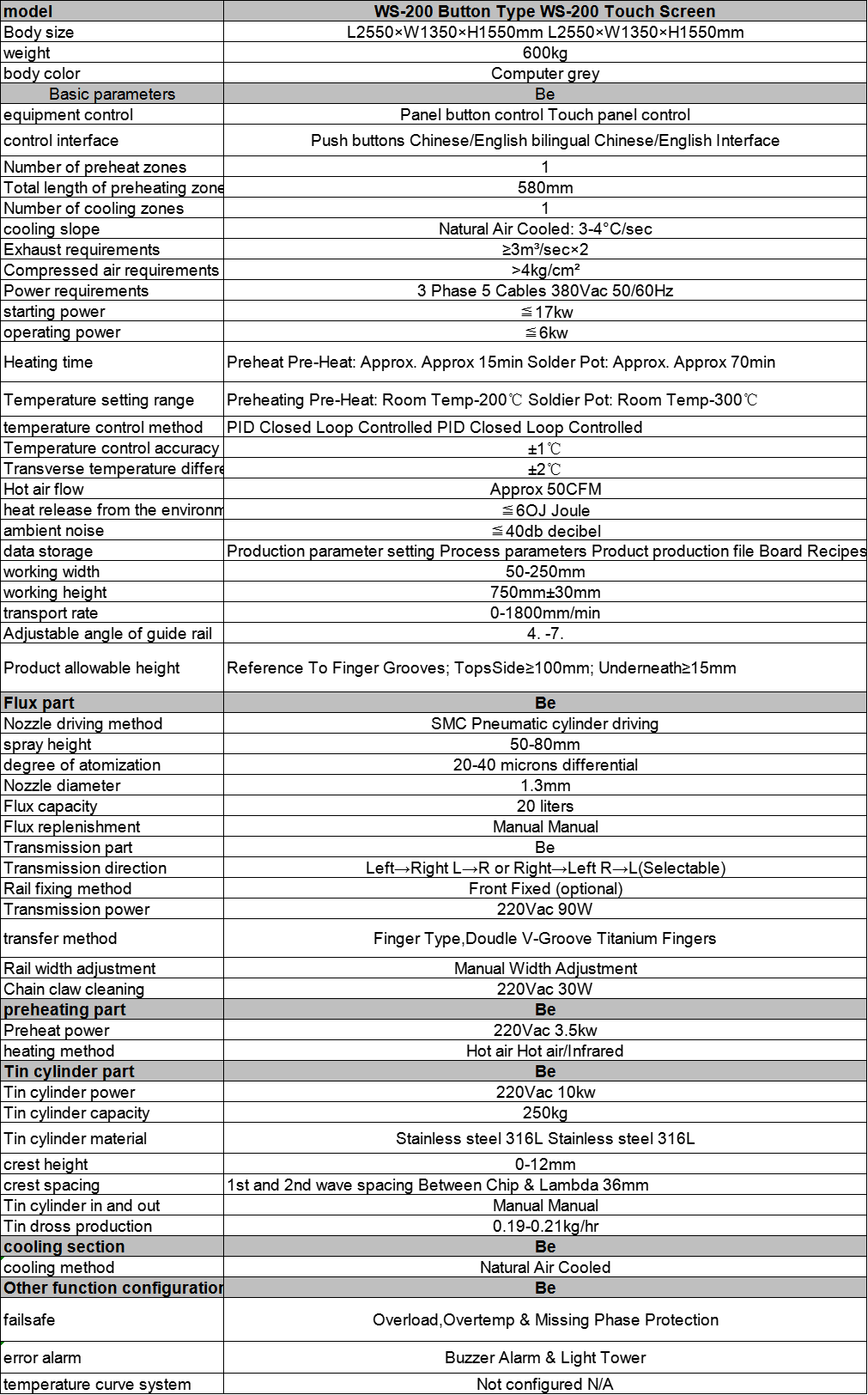

Wave Soldering Specifications